How to Make and Run a Joe Cell

Introduction

What follows is a presentation of material taken from a video-interview conducted with Peter Stevens on 23 April 2006, and reordered into categories that are important to the cell builder. It is not a full explanation of how to make and run a Joe Cell. It relies on the reader having a background in cell work. The quickest way to get that background is to read “The Experimenter Guide to the Joe Cell” (hereafter “the Guide”). This document emphasizes, adds to, and in some cases modifies, what you read in the Guide. Readers will also need a copy of the cell drawings, as found on the Yahoo group Joecell2, alongside them when reading the section entitled “Cell Design”.

Electricity

In order to talk about the use of electricity in cell work (“cellery”) you have to get used to an alternative way of thinking about how electricity works.

In school we were told that the negative terminal and the positive terminal of a battery delivered no electricity at all to an open circuit and that a load was required across the battery positive and negative terminal for electricity to flow. Well according to the view of electricity you are going to get here that view of electricity is incomplete. The negative terminal of a battery is active when connected to a load without any connection, or involvement at all, with the positive terminal. This may also be true of the positive terminal, but the positive terminal is not used alone in cellery. In what follows, the action of a negative terminal of a DC power source with no positive attached will be referred to as “negative electricity”, When talking of negative electricity the term “load” is also rather misleading so it will not be used again.

Applying Electricity

In applying electricity to cell work, one general rule that comes up repeatedly is as follows. When you want to charge water in a cell or charging vat, you first apply negative electricity, then you attach your positive lead (and normal electrical current will flow); then you take off the positive lead and return to negative electricity; then you (sometimes) take off the negative lead. We will call this “the negative first and last, rule”. Please take careful note that you should not rush steps one or four when you apply this procedure. When you put on that negative lead allow significant time to elapse before you put on your positive lead. It is doing something!

Closely related to this procedure are two principles of the application of electricity in cellery. The first is that the energy we are dealing with is negative in charge and is therefore attracted to positive. It follows from this that you put your negative potentials where you want your energy to flow from, and you put your positive potentials where you want it to flow to.

BUT that is just to get things started. You take the positive off pretty quickly because the second principle is that the energy does not like positive electricity at all, so you want to minimize the involvement of positive in the entire process of cellery. Timings are given below.

Power Supplies

For your electricity supply use a 12v car battery, a 12 volt battery charger that delivers preferably linear (not pulsed) DC, or a variable DC power supply set to about 12 volts of preferably linear (not pulsed) DC.

Magnetism

It isn’t that important that your cylinders be of very low magnetism. Magnetism does have a negative effect on the good working of the cell, so it is preferable to have good quality (low carbon) steel if that can be arranged easily. If that is not available, the effects of magnetism can be overcome as follows.

-

Line up all your seams (assuming you are not using drawn tubes). The seams are often the most magnetic part of the tube so by lining them up you only have one segment of the cell that may be of reduced effectiveness. If, after doing that, you have tubes or seams that you suspect are interfering with cell performance because of magnetism there are three more ways to go.

-

Striking and sparking the cylinders. Get a 12v battery and align it with its negative pole East and its positive terminal West. Put your negative lead on the outside of the base of the tube. Then strike the cylinder along its seam with a hammer (along its length if there is no seam). Then spark the inside of the tube at the top with your positive. Then take off your negative. The striking of the hammer disrupts the alignment of the ions Note: it is essential to spark your tubes if you have polished them .

-

Cylinder rotation. Take the cylinder that you think may be at fault and rotate it 90 degrees clockwise.

-

Cylinder inversion. Cylinders have lengthwise alignment of magnetic-type swirl of frequency. You want all your North poles (positives) at the top and all your South poles (negatives) at the bottom. The way you test the cylinders in this regard is with an L-rod which is a type of divining instrument. John Carter is the expert on this and he has put up comprehensive instructions elsewhere. Also, check out Walter Russell on this, he explained what he termed “twin field poles”.

An alternative way of assessing which cylinder(s) should be inverted is to get all your cylinders standing up on your bench and crowd them together (not nested). Leave them for minute and then place your hand on top of the entire set. You will feel heat in any cylinder that is in opposite alignment to the rest.

Cylinder Cleaning

Only ever electro-clean the cell cylinders. Therefore, do not chemically clean them! To do this you reverse the current along the length of each tube with the cell fully assembled.

Start with the outermost cylinder.

(i) Put your positive on the inside skin at the top of the cylinder and your negative on the outside skin at the bottom. Leave this in place for one minute.

(ii) Put the negative on the inside skin at the top and your positive on the outside skin at the bottom. Leave this in place for one minute

(iii) Repeat (i) above.

When you have done this to the outermost cylinder go on to next cylinder until all the cylinders have had the treatment.

Water Cleaning and Charging

You can use water out of the tap as long as you largely clear it of the chemicals put in there by the water company (alum, chlorine, fluorides etc.). To do this you can use a cell.

Put your tap water in the cell then do the procedure described above under “Applying Electricity”. No electrolyte should be added.

Attach the negative of your 12-volt battery, battery charger or 12 volt DC supply at the base of the cell and leave it on for between 2 and 20 minutes. Then, leaving the negative in place, put the positive at the top of the cell’s outer cylinder for between 2 and 3 minutes. Then take off the positive, and leave the negative on for up to an hour.

Pour the water into a glass container or plastic bucket. Repeat.

After 24 hours, the chemicals in the water in the bucket will have become solids; some will have dropped to the bottom and some will have risen to the top, depending on what charge they acquired in the process. Pour off the solids at the top, then pour the middle (clean) water into your cell, then throw away the stuff in the bottom.

Although you can use pulsed dc for this, flat dc works faster.

If you do the same process as above with a charging vat, you will wind up with a good deal more water and no need to fiddle about with repeating your charge procedure. In passing, and while we are talking about charging vats, those cones that you see in The Experimenters Guide to the Joe Cell come from the kind of milk/cream separators used in dairies.

Cylinder Spacers

These should be of natural rubber without additives. Some Buna-N O-ring material works but some O-ring material is mineral based, or contains iron in the colouring which will short out the cell.

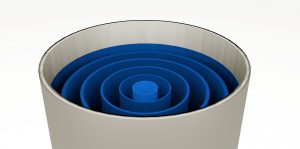

If the spacers are of tubular rubber they should be set with the tunnels of the tubes all pointing inwards towards the centre of the cell when viewed from above. (see image below). It is important to get this detail right to prevent shorting.

The insulating capacity of the spacers is further enhanced by adding a dab of white Sikaflex 291, Marine Grade, to the ends of each spacer.

Spacer at the base of the cylinder set

This should be of alabaster or the same plastic used in kitchen cutting boards

Cell Design

The following is expressed as a set of deviations from the design found in The Experimenters’ Guide to the Joe Cell.

Bill’s drawings, as found on joecell2, are right. Have them by you as you read this. Note that any deviations in this text override the drawings.

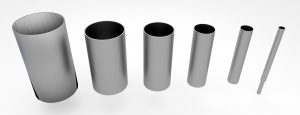

As your central cathode, a 1-inch tube is too narrow, allowing the energy insufficient space to resonate. Use a 2-inch tube as your cathode.

Apply your negative charge to the outside skin of the 2 inch tube by means of a plinth or cathode hub-platform that sits at the base of the 2 inch cylinder (see images below).

Readers will recognize that this instruction is contradictory to the Guide which has the negative charge delivered to the inside skin of the central tube by means of a press fitted bolt. It also contradicts Joe’s statements in the transcripts available in joecellfreeenergydevice Yahoo!Group.

The argument behind this way of proceeding is that the energy seeks positive charge, and you want that energy in the middle of the cell. By putting the negative on the outside skin of the central tube you cause an attractive positive charge on the inside skin, and the energy migrates to it.

In order to have water flow in your 2 inch cathode cylinder you must drill three holes in the plinth or cathode hub-platform.

You can use a flange top or cone top as you wish. because cone tops are harder to get and cost more, a flange is indicated.

Cell Placement

This can be anywhere convenient but it must be at least four inches clear of the high-tension leads and electrical gear (distributor, etc.), and also four inches from the radiator, air-conditioning hoses and fuel lines.

Cell Fastening

Use an embracing clip or bracket; note that it must be VERY well insulated. The cell shorts out to the car very easily and it does so INVISIBLY. In order to prevent shorting, the cell must be insulated from the bracket and any other metal nearby. The preferred insulators are 3 layers of double laminated Hessian sacking, (also known as burlap). This material is wrapped around the cell. Then place a set of three wooden dowels equidistant around the circumference of the cell and brace the entire assembly in your bracket. The effect of the dowels is to create an air gap between the cell and the bracket that further reduces the likelihood of the energy shorting to ground.

Note: natural rubber will not work as an insulator in this application. You need the plant fibers and wood.

Flashing the Cell

Do this as a matter of course before engaging the cell. However, please note, it can be used as a procedure to normalize a cell if you should fail at some point to follow the negative first and last rule.

Connect your negative lead to the base of the cell and spark the positive off the top of the cell with the terminal of your positive lead, four times.

Sparking the crankshaft pulley

So you have your cell all made and lined up correctly; you have your good water inside it; you have your cell fastened properly in the car; it and your aluminium conduction pipe are all clear of the electrics. The next step is to spark the crankshaft.

The way to do that is to start the engine, then get the negative of your car battery attached to your cell. Then take the positive lead [of the car battery] and arc it to the pulley (the exposed bit where you view the timing) four times. Flash a few sparks along the aluminium conduction pipe for about 3-4 seconds. This makes the engine positive and the energy will go there, and stay there. If this is not done the energy will escape to ground by jumping across to whatever is nearby in the engine compartment or it will get absorbed into, or blocked by, gasket material. This jumping across and blocking is invisible so you will not know it is happening. Further research is required to understand this phenomenon.

WARNING : THIS PROCEDURE IS DANGEROUS! WHEN DOING THIS KEEP WELL CLEAR OF ALL THE MOVING PARTS SUCH AS THE FAN BELT ETC.

Conduction Pipe

The pipe should be of aluminium.NB. Copper has the wrong charge. Like the cell itself, it must be at least four inches clear of all the electrical gear in the car. On the end of the conduction pipe, put a snug-fitting sleeve of clear plastic tubing about 4 inches long.

You will begin to condition the engine by having the conduction tube fitted to the vacuum port of the carburetor. To prevent the cell from shorting out dead, leave a 3/4-inch gap between the end of the conduction pipe and the vacuum port. This provides a spark gap to the engine. As Joe states, “The negative Earth outside the Joe cell and the tube are both positively charged, thereby holding potential. The frequencies are able to travel through any steel quickly and effectively”

Connection of the Conduction Pipe and Adjustment of Timing

AAA Connect the conduction pipe to the vacuum port of the carburetor intake manifold which is under the carburetor air intake. Remembering to leave that 3/4″ (20mm) spark gap!

Connect the positive 12v DC lead to the outside of the cell container. Start the engine and it will draw the gas/energy in. Allow this to go on for three minutes. Then, remove the positive lead from the cell and electrically connect it to a long-handled screw driver. Arc the crank with the screwdriver by just touching the moving outside rim on the crank.

Sparks should fly as you zap; do it for just 1 second, equivalent to 4 sparks. Keep clear of fan belts and other moving parts while you do this. Stop the engine. Disconnect the fuel line and block it with a suitable bolt. If your fuel pump is electrically driven, it will obviously have to be disabled.

WARNING : THIS PROCEDURE IS DANGEROUS! WHEN DOING THIS KEEP YOUR HANDS AND THE SCREWDRIVER WELL CLEAR OF ALL THE MOVING PARTS SUCH AS THE FAN BELT ETC.

Note 1 LEAVE ATTACHED ONLY THE NEGATIVE LEAD.

Note 2 Don’t put an electrical shutoff valve in the fuel line

Now loosen the bolt securing the distributor place, put a reference mark at its current position and advance the timing 10 degrees. The engine should still run on the fuel that is left in the carburetor. The engine will now start to cough. Advance the distributor to about 30 degrees from where it started. This will equate to 60 degrees on the crank. Have an assistant turn the key and rev the engine for you. As the engine continues to cough keep moving the distributor around until the running of the engine becomes smooth. You will notice a gasping sound and the engine will slow, nearly to a stop, then it will pick up again, then slow down. It is wavelike, something like breathing. Don’t touch the cell once you are running. Fine tune the timing. Then fasten your seat belt.

BBB The next step is to attach your conduction pipe to a bolt (sometimes called a “blind lug”) set into the engine head. The bolt should be located in the valley of the V of a V form engine, if that is what you have. But in most situations you will have to attach to a bolt placed wherever you can. The engine should work right off with only minor changes to timing required.

You are running without petrol!

[Note: Joe no longer attaches the conduction tube to the vacuum inlet of the carburetor connection at any time, but it is suggested here as a way to start the conditioning of the engine. Once the engine is operating well by means of the cell’s attachment through the carburetor, proceed to use the inset bolt as the pathway to the engine.]

Tips and Points of Interest, in no particular order.

-

If you are near HT overhead power lines the cell will stop. You overcome this by using a 1.5 volt battery. The negative terminal is to be run to the cathode cylinder, and the positive to the cell container. This just gives the water potential, and then it holds that potential.

-

TIG weld using only inert gas not an oxidising gas.

-

If you are losing cell-water either (a) the foam from the cell is getting sucked into the engine (obviously this can only happen when you are in phase of being connected to the carburetor). Alternatively your cell is shorting out and drawing in air

-

Cells often change the weather if you are charging and using them outside

-

Bill got threatened because he was successful, because he was excited and talked a lot and convincingly, because he made a video, and because he was not publicly known. Who exactly did it to him it is not known. His local Police have been informed.

-

Stability. Unstable cells are leaky cells. There is no trick to cell stability other than ensuring no leaks, no shorts.

-

If you roll your own tubes, stitch weld only at the top, the bottom, and midway in the cylinder. The gap between the un-welded edges is where a lot of the gas and the energy comes away from.

-

Scum in your cell caused by leaving normal DC electricity on for too long and can be cured by temporarily reverse charging the cell. Empty the cell and refill with good water. First, connect negative on the outside of the cell and positive on to the middle cylinder for two to three minutes. Then switch your terminals back over for one minute. Empty the container out and all the scum goes with it.

-

You can have fun sparking your HT lead into your test cell. See what happens!

-

Play your cell music and notes. It may like F sharp!

-

Joe’s first conversion was of a Rover 3500-V6, then a Leyland P76 1992.

-

Joe can make cells start by willpower!

-

You are a cell. You can start yourself!

-

Everyone reckons they can improve on the cell construction and implementation. It seems that we all want to be like Frank and say “I did it my way”. That is recipe for a lot of work and very probably no results, yeah but Lots of Fun!

Source: PESN.com